Our Projects

Mechanical & Structural Design

TBM Cooling Tower Platform - Design of steel structure, access system and pipe supports for North East Link tunnel boring machine (TBM) cooling water system.

Industrial Water Tank Pipe Support - Project involved routing and support of steel pipe along TBM launch site and to the top of water tanks, without modifying the proprietary tank design.

Escalator Opening Moveable Platform – Custom access platform capable of traversing ‘escalator openings’ in pre-cast mezzanine levels. The design allowed the structure to be lifted into position from beneath the opening and transition from travelling on castors (including between adjacent openings) to being jacked up when in use.

Pier Head Access Platform - Project involved design of a highly custom, crane liftable, platform and connecting bridge used to provide safe access to pier heads during bridge construction works. Due to the complex construction methodology, the design included the ability to split and lower half-sections during disassembly, once the segments had been installed above.

TBM Tunnel Jet Fan Support Frame - Ignite completed the design of multiple steel support frame to suspend ventilation jet fans overhead within the Cross River Rail tunnels. Design included the specification of post-installed anchors into tunnel segments.

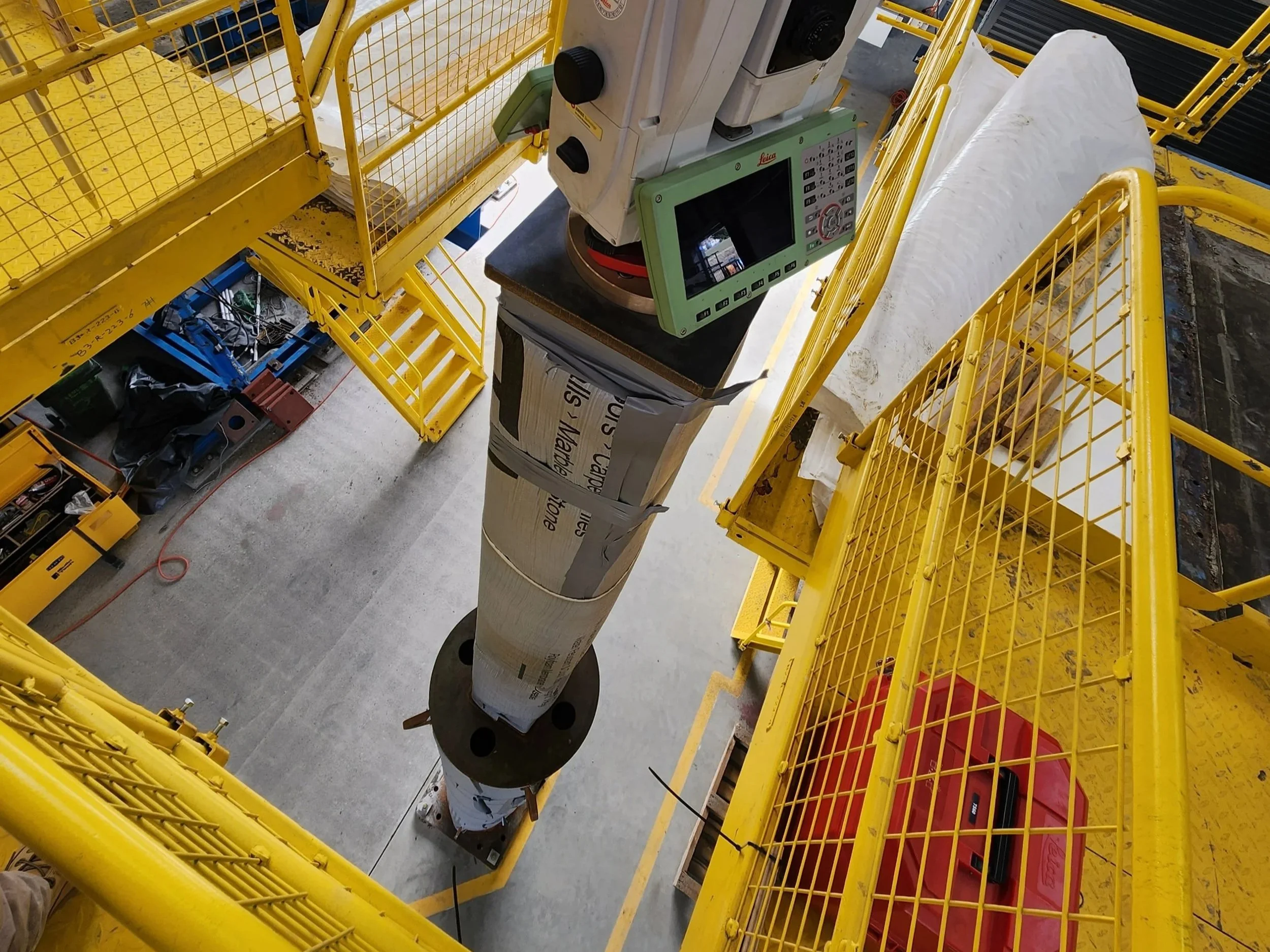

Bridge Segment Survey Tower - In order to meet strict lateral movement of sensitive survey equipment within a bridge segment casting shed, Ignite designed a 6m water-filled and insulated steel tower that controlled the thermal movement of the structure.

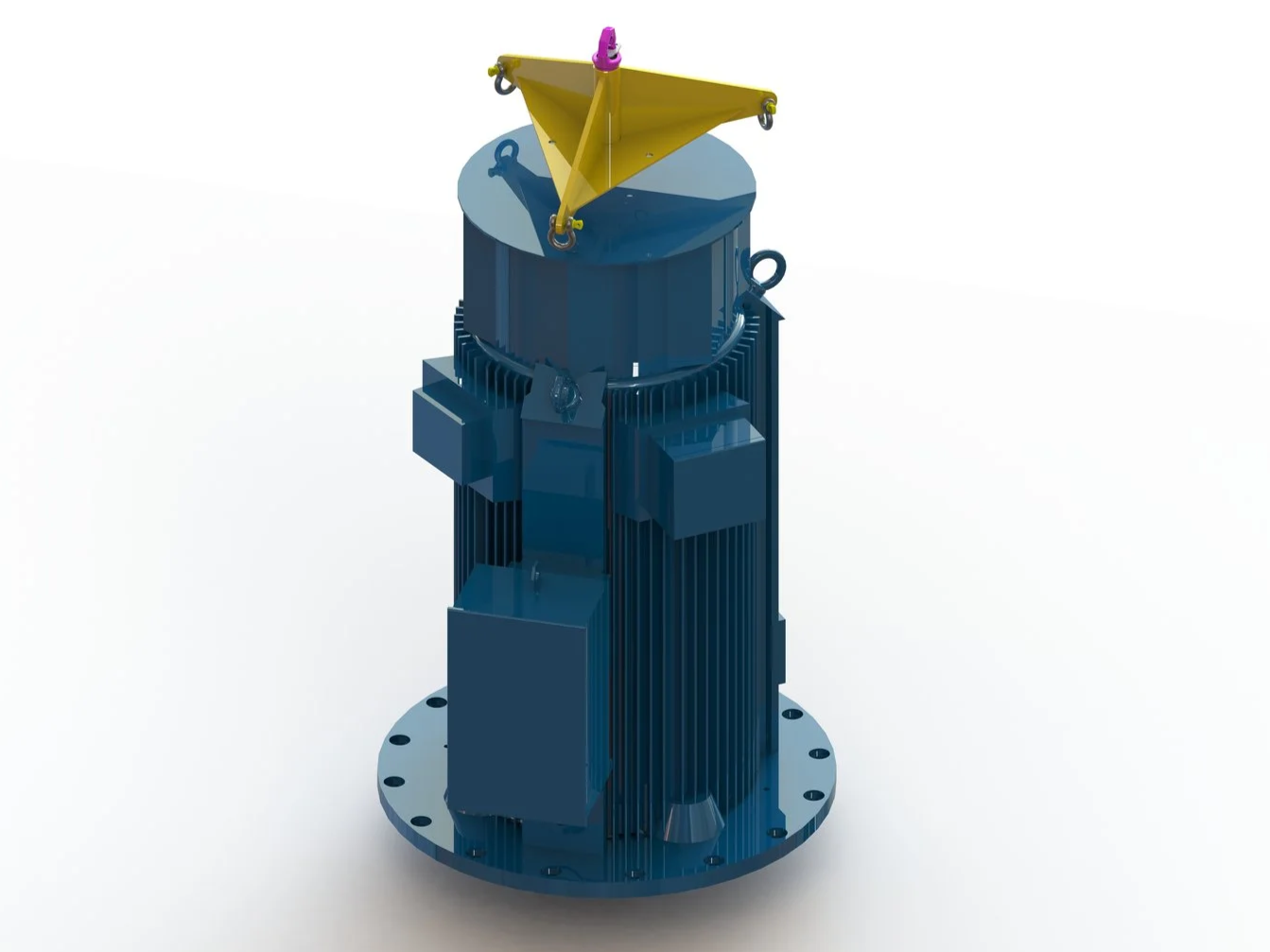

Dry Well Motor Lifting Frame - Ignite designed a custom tri-arm lifting device to allow the handling of multiple 6t motors within a dry well of the wastewater treatment plant. Equipment was designed to ensure compliance with AS4991.

Recycling Plant Ventilation Duct Supports - Project involved the site measure and design or structural steel supports for an external and internal ventilation ducting upgrade.

TBM Tail Shield Vertical Propping - Due to launch site space constraints, the 15.5m diameter structure was required to be stored in the vertical (operating) position ahead of assembly to the rest of the TBM. Load cases designed for included wind, seismic and accidental impact.

Surge 4 Small Sites Access Upgrade - Project involved the design of nine (9) unique access systems to service mains water infrastructure in and around a major Australian airport. Ignite were engaged to complete this work by the fabricator, BDR Stainless.

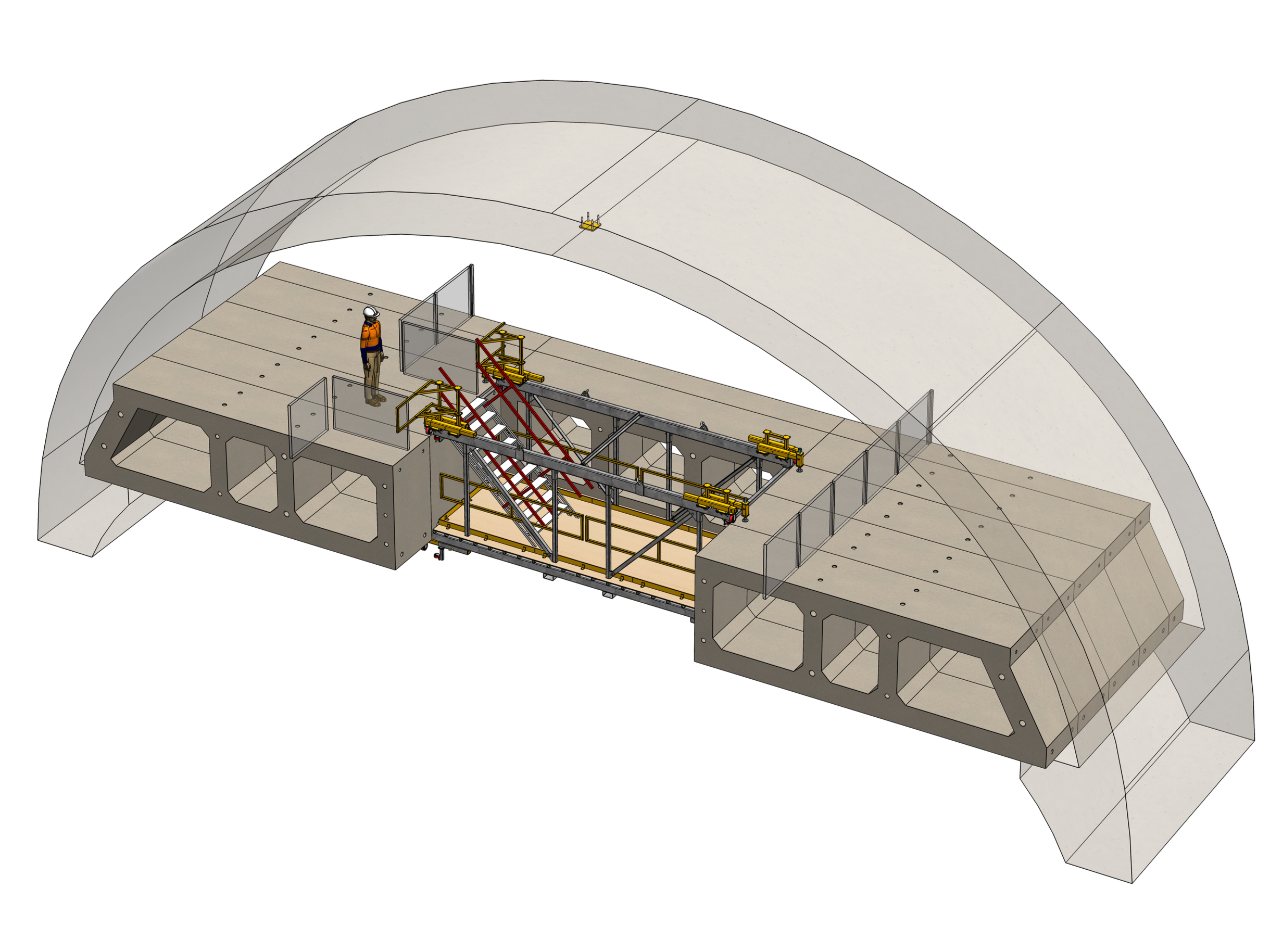

Ignite Engineering was engaged to design a temporary steel structure to cover the dive portal of the Adelaide Street tunnel, during construction within the Brisbane CBD, as part of Brisbane City Council’s Brisbane Metro project. The structure’s purpose is to assist with noise and dust mitigation during tunnel construction and provide an area onto which the site offices and amenities could be installed.

Ignite was engaged to design a custom structural steel frame used to lift and transport 6.7t concrete culverts (up to three at a time) on a major underground construction project. The arrangement involved the re-purposing of an existing pre-cast segment transporter (shown in yellow).

1,110kg Monorail modifications – Following a 3rd party review of an as-built monorail design, it was determined that the deflection at the free-end of the cantilever span did not meet the requirements of AS 1418.1/18. To ensure compliance without the need to decommission the structure, Ignite designed of a simple add-on modification to improve rigidity.

Bag Roll Handling Hoists – Ignite was engaged by a major food supplier to provide a solution that improves operator safety during periodic replacement of 175kg plastic bag rolls on bagging line equipment. The custom hoists allow the rolls to be lifted off adjacent pallets and be orientated to suit the machine installation requirements.

Concrete Drop Pipes – Ignite was engaged at short notice to complete the design of two (2) concrete drop pipes to deliver concrete from agis at ground level into tunnelling agis, 27m below. The design included hoppers, kettles and 10” diameter suspended pipework.

Escalator Opening Moveable Platform – Project involved the design of a custom access platform capable of traversing ‘escalator openings’ in pre-cast mezzanine levels. The design allowed the structure to be lifted into position from beneath the opening and transition from traveling on castors (including between adjacent openings) to being jacked up when in use.

150t Roack Bolt Stressing Chair - custom stressing chair to be installed in the tunnel lining on the Kidston Pumped Storage Hydro Project. The stressing chair was designed with the purpose to perform proof load testing of rock bolts.

Disc Mill Housing Redesign – Project involved redesign of the outer housing of an OEM product to include stainless steel (instead of cast iron) and be openable to allow for daily cleaning of the internal mechanisms. The housing was designed to contain a failure of the 50kg flywheel/disc plate rotating at up to 3600 RPM.

Mezzanine Segment C-Hook – Ignite completed the design of a AS4991 complaint lifting device to enable the installation of pre-cast concrete segments up to 25.0t. The C-Hook was designed to interface with a Hyster Reach Stacker normally used to lift shipping containers.

Mezzanine Segment Lifting Beam – Project involved the design of custom AS4991 compliant lifting device to install 24.0t precast concrete segments. The beam featured an adjustable carriage and a swivel to allow for the variable segment CoG and attachment to a Hyster Reach Stacker.

Concrete Pump Line Column – Ignite completed the design of a 50m high structural steel column used deliver pumped concrete from street level into the deepest excavation to ever be completed in the Brisbane CPD. The column supports four (4) 5” pump lines and additional services.

30t Jacking Frame – Due to restricted head room within a factory, Ignite was engaged to design a custom jacking frame to remove and replace a large piece of machinery. The modular design uses synchronised hydraulic cylinders to safely raise and lower the load.

High School Stairway Design – Ignite completed the design and workshop-level drafting for two (2) stairway towers to suit modular school buildings constructed in Brisbane. The project was completed at short notice and certified as compliant to AS 1428, AS 4100 and NCC requirements for schools.

CrossRiverRail - Albert Street Stairway Hanging Frame – Ignite completed the design of a steel support and access system structure used to suspend an existing Calbah patented stair system (up to 30m high) over the station box. The design was completed in accordance with the requirements of AS4100 and AS1657.

Roma St Cavern Services Bridge – Ignite was engaged at short notice to design a 1.0t steel structure to allow pipe work to span 12.5m across an auxiliary passage. Design, fabrication and delivery was completed in partnership with Blask Engineering in less than 2.5 days.

Cross River Rail Roma St 3.5m Ramps – Project involved generation of a 3-piece ramp design to allow passage of construction vehicles over a 420mm variation in slab height and protruding reinforcing steel. The ramps were designed to be easily relocated and support vehicles with GVMs up to 80.0t.

Water Treatment Plant Access Upgrade (Site 1) – Ignite completed the design of a custom aluminium stairway in accordance with AS1657 and AS1664.1. The access system improves maintenance access to a remote scour valve.

Water Treatment Plant Access Upgrade (Site 2) – Ignite completed the design of a custom aluminium access system including reinforced concrete footings. The walkway/platform provides safe access to a raised scour valve spindle.

Water Treatment Plant Access Upgrade (Site 3) – Project involved the design of an aluminium stairway, walkway and ladders to provide a safe means of access into basin inlet races. Design included integration of a davit system for operator recovery.

Tender Cradle Design – Ignite was engaged to redesign a hydraulically driven aluminium ramp/cradle on a commercial vessel. The project focused on improving the original design to ensure compliance with AS 1664.2.

TBM Removal Winch Frame – Used to extract tunnel boring machine components, Ignite designed a fabricated steel frame to allow for installation of the winch onto existing site steel work. Frame was rated to a maximum line pull of 150kN (15t).

Cross River Rail MSV Ramps – Ignite completed the design of a custom steel ramp arrangements used at both Roma St and Woolloongabba Stations to support tunnel construction. The modular design of the ramps allowed for two (2) variations of both width and height as required, including installation within the TBMs.

Boggo Rd Pump Line Support Column - As part of the Cross River Rail project, Ignite designed a custom steel column used to enable routing of high pressure concrete pump lines from ground level down into the underground cavern excavation.

Cross River Rail – Substation Jacking Frame – Ignite completed the design of a custom jacking frame that allows for the transport & lifting of 5t TBM electrical substations. Jacking frame designed to fit with specialised tunnelling vehicles.

Cross River Rail – Substation Support Frame – Project involved the design of a custom support frame used to secure 5t TBM electrical substations during tunnel construction.

Sand Hopper Access System – To ensure compliance with the Code of Practice for Managing the risk of falls in the workplace & AS1657, Ignite designed an upgrade to allow for safe access into a 6m deep sand hopper on a dredging vessel.

Cross River Rail – Storage Gantry. Project included design of a structural steel storage gantry in accordance with AS4100. The gantry is rated for an imposed load of 10kPa over an area of more than 450m^2.

Tunnel Segment Cradles - Project involved design & certification of a steel cradle arrangement made from repurposed TBM launch beams. Each cradle was rated for the on-site storage of around 26t of segments.

Cross River Rail – Woolloongabba Overhead Walkway – Ignite was engaged to design a temporary steel structure to provide a direct link between the construction area and the site office/amenities. The project included a 16m free spanning walkway and multi-level stair tower.

Cross River Rail – Conveyor Booster VSD Frame – Project involved the design of custom frame to support electrical VSDs required for the operation of TBM spoil removal conveyors. Design included a foldable platform to provide sufficient clearance to vehicles within the tunnel.

Cross River Rail – Woolloongabba Station Site Office Patio Extension. Project involved the design of modifications to an existing structure with the aim of integrating it with other future site establishment projects.

Calford Anti-Tack Stage 2 – Following a successful trial of the original upgrade, Ignite were engaged to design, manufacture and commission the system which uses pneumatic valving and custom stainless steel diverters to direct fluids used in the manufacture of rubber.

Cross River Rail – CP7 Monorail – To allow for the lifting of construction equipment during excavation of a low-point sump between the two (2) tunnels of the CRR project, Ignite designed a 3t lifting monorail in accordance with the relevant Australian Standards.

Ventilation Fan Support Frame – Ignite was engaged to design a structural steel frame which supports a 10t tunnel ventilation fan in accordance with AS 4100. Working along side the fabricator, the frames were designed, built and delivered to site within 7 days.

Pressure Vessel Access Platform - Ignite completed the design, 3D modelling and workshop-ready drafting of a custom steel access system to ensure compliance with AS1657 and AS4100.

Mock Marine Gearbox Jig – The project included the design of a custom substitute gearbox to suit a government vessel. The jig was required for in place driveline alignment while the original units were being refurbished.

PCB Barrier Screens – Project involved the design and certification of custom 4m high barrier screens to be attached to the top of standard precast concrete barriers. The screens are used to isolate workers from crane lifting operations and heavy vehicle traffic.

Auto Die Gate Lifting Frame – Ignite was engaged to design a custom monorail lifting frame in accordance with AS 1414.18. The frame is required to safely remove pieces of equipment (up to 1,200kg) due to limitations on mobile crane access.

Caboolture Hospital Redevelopment Stage 1 Office Gantry (Ausco Modular) - Project included design of a steel support structure, footings, covered stairways, raised access decks and maintenance access platforms.

Cross River Rail - Dewatering Tanks. Ignite performed the design of two (2) large steel tanks used to store and separate up to 180,000L of water/solids after it is pumped to the surface during tunnelling works.

Seadeck Star - One of our more unusual projects. Ignite was engaged to generate a 3D model and manufacture drawings for a custom 5-point star on the party boat 'Seadeck Australia'.

300kN Tensile Test Coupling – Ignite was engaged to design a custom machined steel coupling used to connect M30 to M33 threaded bar as part of proof load testing of underground rock bolts.

Cross River Rail - Boggo Rd Construction Site Office. Ignite was engaged to perform conceptual through to detailed design of the complete 3-storey support structure, stairways and elevated walkways.

Cross River Rail - Woolloongabba Construction Site Office. Project included design and as-built inspection of steel support structure, stairways, covered areas, maintenance access walkways.

Anti-Tack Solution Upgrade. Ignite performed the mechanical design, manufacture and commissioning of the system which included an in-ground stainless steel diverter sump, pump skid, tank weigh-frame and associated pipework/equipment.

Cross River Rail - Boggo Rd Covered Walkways. Design of structural steel and cold-formed steel roof structures to provide shelter to construction personnel. This project was completed as an addition to the main structure originally designed by Ignite.

Super Yacht Genset Lifting Frame - Designed lifting frame and custom low-headroom lifting trolley to allow for the safe removal and replacement of main and emergency generators.

Tank Support Remediation Design - In order to extend the service life of elevated stainless steel storage tanks, Ignite Engineering was engaged to design and draft a custom support arrangement. The upgrade was integrated into the existing steel structure to minimise the cost of the temporary solution.

Analysis & RPEQ Certification

TBM Cutter Head Stooling Stability - Project involved the assessment of the proposed stooling arrangement to ensure compliance with AS1170 principles. The cutter heads had a mass in the order of 400t each and a diameter over 15m. Load cases reviewed included seismic and accidental impact.

Ignite was engaged to perform 3rd party engineering verification of a Pipeline Jacking Frame to be used as part of a pipeline renewal project. The jacking frame was used to temporarily raise sections of the pipeline off the existing bearing pads to allow for replacement.

Base Plate Proof Load Testing - Due to irregular anchor placement on a complex steel structure, Ignite designed and operated a custom 23t test rig to perform proof load testing and validate structural performance as per AS1170.0 requirements.

Sewer Main Vent Arrangements - Ignite completed the 3rd party review and as-built inspection of a series of aluminium access systems and stainless steel vent pipes. The project aimed to improve operator safety during periodic venting events.

Construction Hoarding Wind Loading Assessment - Due to proximity to an active rail corridor, Ignite was engaged to review and certify a temporary form ply / precast concrete barrier hoarding arrangement for both strength and stability against AS1170.2 wind actions.

Column Load Monitoring - Project involved the installation and regular monitoring of vibrating wire strain gauges. Engineering analysis was performed using the data obtained with the aim of ensuring the concrete supporting structure was not exposed to reaction forces in excess of strict design limits.

190t Transformer Support Arrangement – Ahead of the arrival of a large electrical transformer to the Port of Brisbane, Ignite was engaged to assess and certify existing fabricated beams and support stands used to store the equipment prior to site transport.

Peanut Cage Certification - Project included detailed 3rd party analysis of custom steel cage designs being manufactured overseas. Ignite was able to ensure compliance with the relevant Australian Standards prior to placement of the order.

Process Vessel Refurbishment - Ignite completed the periodic strip down, inspection and refurbishment of a lagged and clad pressure vessel in accordance with the requirements of AS 3788-2006.

Chilling Tunnel Compliance Review – Ignite was engaged to perform a 3rd party engineering assessment to ensure compliance of the mechanical/structural equipment in accordance with the relevant Australian Standards and the Professional Engineers Act 2002 (QLD).

Hatch Lifting Points – To enable the safe removal of a ship’s steel access hatch prior to a maintenance docking, Ignite assessed the as-built detail and specified a lifting arrangement in accordance with the relevant Australian Standards. Project turn-around was achieve within 24hrs, over a weekend.

Engine & Pump Room Monorail Analysis – Ignite was engaged to perform a 3rd party engineering assessment to calculate a rated capacity for a series of steel monorail beams required to be used during maintenance of the ship.

200t Crane Outrigger Pad Verification – Ignite was engaged to perform the 3rd party verification of a 6m2 fabricated steel outrigger pad design. The project involved detailed FEA to ensure the compliance of the light-weight design in accordance with the relevant Australian Standards.

Pipe Bracket Certification – Ignite was engaged to analyse and certify a steel bracket design which supports steel pipe used for pumping concrete during construction works. The assessment included all potential orientations and configurations to ensure compliance with AS 3990 and AS 5216.

In-service Pressure Testing - Project involves the annual testing and inspection of process oil vessels using a custom nitrogen pressure test rig. Testing and inspection performed in accordance with a procedure developed to meet the requirements of AS 3788-2006.

Transport Cradle Certification – Ignite was engaged to perform the theoretical assessment and certification of a fabricated steel cradle design to be used to transport over 20,000 concrete tunnel segments from the manufacturer to a major Brisbane construction project.

5t Rigging Box Verification – Project involved the 3rd party design verification of a sheet metal box as per the requirements of AS 4991-2004 – Lifting Devices. The boxes are to be used to store and transport crane rigging equipment.

Inlet Flow Splitter Tank & Access System. Ignite performed the design assessment and as-built inspection to ensure compliance with the relevant Australian Standards.

Peanut Cage Load Testing – Ignite performed physical hydrostatic proof load testing on a series of fabricated steel cages to validate theoretical performance. This included the preparation of a methodology to reflect requirements for prototype testing in accordance with AS1170.0.

Custom Beam/Column Connection Assessment. Ignite performed detailed analysis using manual calculations and FEA to ensure compliance of the design with 'AS4100 - Steel Structures'.

Peanut Grading Sieve Structural Upgrade. Performed as-built inspections, vibration analysis and Finite-Element Analysis (FEA) on complex structure to minimise displacement caused by reciprocating machinery installed almost 20m above the ground.

Pipe Lifting Basket - Ignite performed the assessment of the custom steel basket in accordance with the requirements of 'AS 4991 - Lifting Devices'. The equipment was later manufactured for use as part of the Cross River Rail project.

A-Frame Crane Assessment. Ignite was engaged to perform the inspection and assessment of a large A-frame crane installed on a sand-dredging vessel. The assessment was aimed at ensuring the crane was safe for continued use prior to its scheduled replacement date.

Super Yacht Prop Shaft 'Whipping' Assessment. Ignite was engaged to perform a theoretical analysis to ensure the main propeller shaft of a 36m super yacht would not be at risk of 'whipping' following relocation of an intermediate bearing.

VacSkip Structural Analysis – Project involved Finite Element Analysis (FEA) and RPEQ certification of the patented product used in the management of contaminated materials. Load cases reviewed included crane lifting, towing and hydrostatic pressures in accordance with the requirements of the relevant Australian Standards.

Product & Innovation Development

35t Workshop Trestle - Fabricated steel trestle originally developed to meet specific project requirements however design is suitable for general usage within a range of heavy industries.

Superyacht Engine Room Mist Eliminators – Design of both inlet and outlet versions included integrated pivoting panels to improve maintenance access while protecting the void from water/sea spray ingress.

‘VacSkip Mini’ model VS0301 - Ignite completed the design of a miniature mobile version of the Patented VacSkip. The new model is intended to simplify the isolation and management of small volumes of contaminated slurry.

Cape Class Patrol Boat Mist Eliminators – Project involved the design of five (5) unique types of surface mount air/water separator to suit the current and future generations of vessel. The hinged design allows for easy maintenance access behind the units.

ACPB Mist Eliminators – Due to the success of the original ventilation upgrades performed on the fleet of Armidale Class Patrol Boats, Ignite was again engaged to complete the design of air/water separators to prevent sea water ingress into the HVAC systems.

Custom Pallet Lifting Cage – Ignite was engaged to design a cage used to lift laden pallets (up to 800kg) into the hold of marine vessels. Due to the restricted space available, the design featured a unique means of engaging the pallets.

VacSkip model VS0201 – The project involved the design of the latest ‘VacSkip’ model which uses concentrated solar energy to heat an isolated liquid which is circulated beneath the floor of the unit. This process further reduces slurry drying times.

VacSkip - Mechanical design of Patented solutions to the storage and drying of contaminated slurry produced as a result of vacuum excavation. Design features a retractable tarp system which closes automatically when rain is detected.

Armidale Class Patrol Boat - Vent Heads. Project involved the design of a custom solution to reduce corrosion due to sea water ingress into vessels via the ventilation systems. Solution successfully installed to all 13 vessels in the RAN fleet.

Landing Helicopter Dock (LHD) Mist Elimination Upgrade. Project involved the design of custom ventilation upgrade to exclude sea spray and rain water from entering the vessels via the ventilation system.

Mist Eliminators - Design of multiple custom air/water separators to reduce sea water ingress into vessels via ventilation systems. Units have been successfully installed on multiple super yachts and Australian Navy vessels.

Custom Radar Mast - Design of aluminium mast to replace OEM equipment on a luxury tender vessel. The boat's European manufacturer later purchased an additional unit to accompany a new built vessel.

Tag Mate. Design of simple device to improve operator safety in electrical switch yards. The 'Tag Mate' provides an easy to locate means of storing and retrieving 'Do Not Operate Board' tags common within the electrical distribution industry.